Unlike other methods of metal forming, forging never compromises the integrity of the final product. The forging process retains the intrinsic strength in the grain of the original piece of metal. Our forging process takes specific advantage of the grain flow, directing it to the most highly stressed points. Each product is forged to provide extra strength at the points of greatest stress. The forging ductility reduces the possibility of failure without warning when subjected to unexpected shock loading.

The forging process offers advantages including inherent high strength and structural integrity, improved mechanical properties, minimal metal waste, overall weight reduction without the loss of strength, affordable method of forming difficult materials, cost-efficient production of complex shapes and combination parts that can be forged in one step.

The finished product is much more reliable for strength and quality than a similar product produced by casting, stamping or machining.

Tool Design

At Keystone we design our tools in-house which saves the customer time and money. Our tooling engineers utilize state of the art programming and computerized solid modeling for part and tooling development. Our engineering data is directly fed into our CNC machining centers which convert that data and manufactures the tooling for each individual job.

Material

Raw material is stored under roof keeping the material from the elements. Our steelyard department utilizes a variety of saws to cut material to length. We forge parts using many grades of material which include carbon, alloy, stainless steel, brass, aluminum and specialty materials as well. All raw materials are fully traceable from start to finish.

Forging

Forging is a process of making parts by shaping metal under pressure to produce a finished good. Each piece is precisely heated to the right temperature, then shaped in a tool until the final product reaches our customer’s exact specifications. The finished product is more reliable for strength and quality than a similar product produced by other means.

Secondary Operations

We have a variety of machines in-house to perform secondary operations for each individual job. CNC machining, drilling, milling, threading, tapping, grinding and more, are all available. In addition, we also offer heat treating services. Having all of these options under one roof makes a product more cost effective for our customer and shortens delivery time.

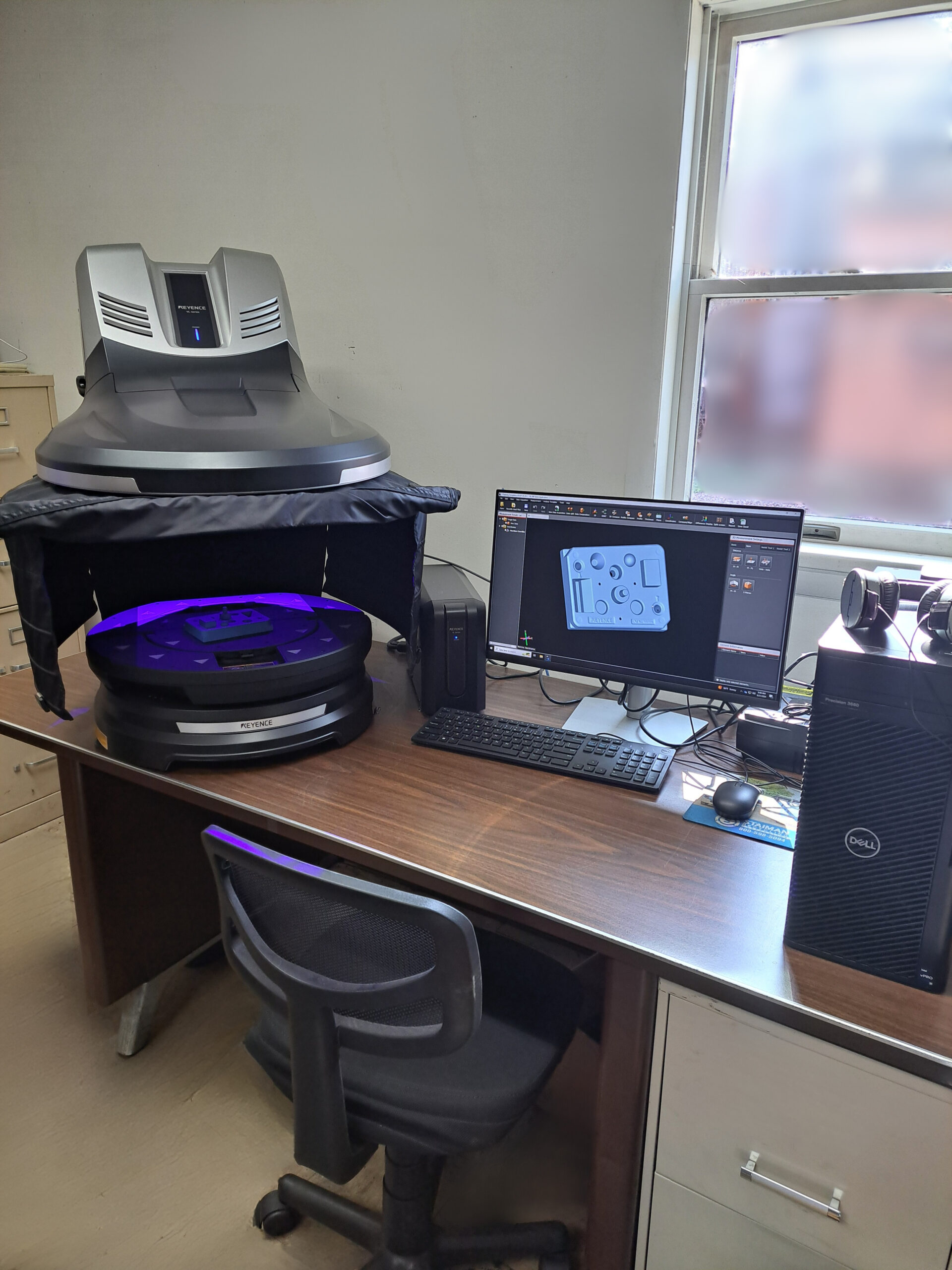

Quality Assurance & Control

Our QC department has complete control of the quality of each job from start to finish. The procedures performed by our trained inspection personnel ensure traceability of each part from the receipt of material to the shipment of finished goods. Inspections are performed during the forging run, through secondary operations and a final inspection at time of shipment. In addition, where applicable, non-destructive testing, Magnetic Particle Inspection and Zyglo for non-ferrous materials is performed in-house. Physical testing to ASME/ASTM and Military Specifications is also available. The end result is a superior product, custom crafted to the exact standards of our customer.